Report

Report number / Item number / Issue Date /

Proportions

Clarity characteristics

Red symbols indicate internal characteristics.

Green symbols indicate external characteristics.

RUBY EDUCATION

Ruby is one of the world’s most celebrated gemstones. Its remarkable hardness and appealing color have been coveted for thousands of years. From symbols of protection worn by ancient warriors to the treasured collections of royal families today, ruby has long been called “the gemstone of nobles.”

Inspired by organic shapes found in nature and permeated with a theme of three, trillion, square emerald, and princess cuts. Celebrating natural forms with a twist of precision, Trio by Âme depicts mathematical, geometric forms for the woman who embraces femininity with strength. With a cluster diamond motif, this emphatic collection is for the woman who is eternally chic, effortlessly cool and ever graceful.

Classification and Value

Ruby comes from the Latin word ruber, which means red. Rubies come in a variety of tones and saturations - but to be classified as a ruby a gemstone must display some form of red. If the mineral variety presents with any other color, it is disqualified from being a ruby. The closest gemstone is composed of identical mineral which presents with a lighter red tone, called pink sapphire.

As with diamond, ruby’s price per carat increases disproportionately as carat weight increases. In fact, natural rubies of high carat weights are so rare that they may command a higher price per carat than comparably sized diamonds.

Rubies were first found in Southeast Asia and later in eastern Africa. Today, the discovery of a new source of rubies in Greenland has energized the colored gemstone world. Close to the coast in a pristine and icy landscape, Greenland Ruby’s Aappaluttoq [Ah-puh-lu-tok] mine, meaning RED in Greenlandic, is nestled within the arctic mountains in the Southwest of Greenland. At nearly 3 billion years old, the rock formation has concealed its valuable collection of rubies until a handful of years ago.

Greenland Ruby

Greenland Ruby, a company committed to responsible sourcing and mining practices, was awarded the license to mine and market rubies from this valuable collection. Believed to be the oldest ruby deposit on earth, each gem Greenland Ruby brings to market has a unique identity and is tracked and traced along every step of its journey, from the Aappaluttoq mine, through careful planning and polishing, to the hands of its eventual wearer.

Craftsmanship

In its natural form ruby is dull and lifeless. It takes human craftsmanship and care to reveal its inner beauty as a polished, vibrant gemstone. The most common gemstones are polished and faceted in the same manner as diamonds, displaying a symmetrical series of flat or triangular facets. Historically the most popular ruby shapes have been oval, emerald, pear and marquise, though any shape is possible.

Rubies can also be produced with rounded tops, and no facets, in a style known as cabochon cutting. This rounded cutting style is versatile for adornment styles including beads and bracelets.

Enhancement

Since ancient times, man has devised methods to improve gemstone appearance. Heat treated carnelian was discovered in the tomb of King Tutankhaman, dating back to 1,300 B.C. Modern treatments have continued to evolve and are applied to nearly all gemstones on the market today.

For ruby, such treatments make it possible to display each gemstone’s natural color to its best effect. And while treatments are common practice, it’s important that sellers disclose the presence of treatments. This is not simply a matter of transparency. Certain enhancements can affect how gemstones must be cared for.

Your Diamond's Creation

Your laboratory-grown diamond is chemically identical to every other diamond on earth. However, instead of mined diamonds, which formed beneath the ground billions of years ago, your diamond was grown in controlled laboratory conditions using sophisticated methods of chemical synthesis. There are two specific approaches to diamond creation:

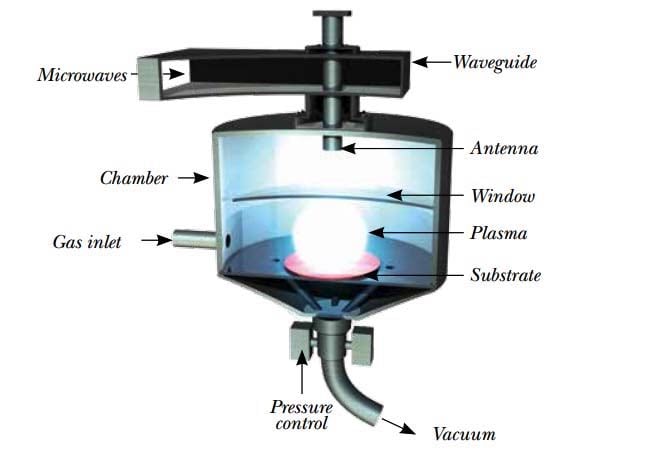

Chemical Vapor Deposition (CVD)

The Chemical Vapor Deposition (CVD) process releases carbon from plasma. This involves superheating hydrocarbon gas in a vacuum to between 3,000-4,000C, at which point the carbon atoms begin to separate from their molecular bonds. Those atoms descend and land on a flat wafer of previously grown synthetic diamond and grow in vertical layers. This substrate is square for jewelry applications but the shape can vary for other applications in medicine, communications and technology.

High Pressure High Temperature (HPHT)

The High Pressure High Temperature (HPHT) process replicates the natural conditions under which diamonds formed 100 miles below the surface due to subduction. A carbon source, a diamond seed and a metallic catalyst go into an octahedral cell. The cell is placed into a massive mechanical press where the contents are heated near 1,500 C and subjected to staggering pressure. The melting metal dissolves the carbon and the pressure causes precipitation to the diamond seed, growing a larger diamond. The level of pressure from these immense presses has been compared to what you’d experience if you balanced a jumbo jet on the tip of your finger.

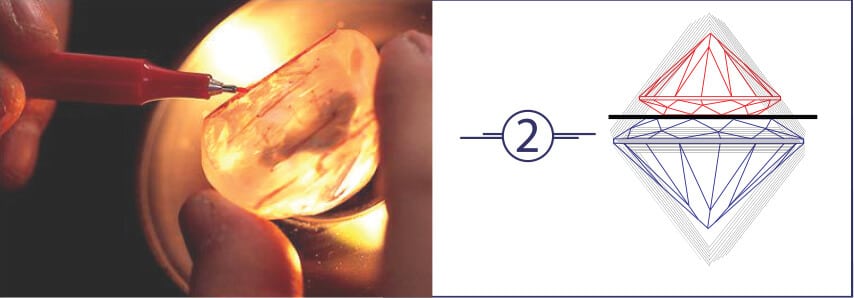

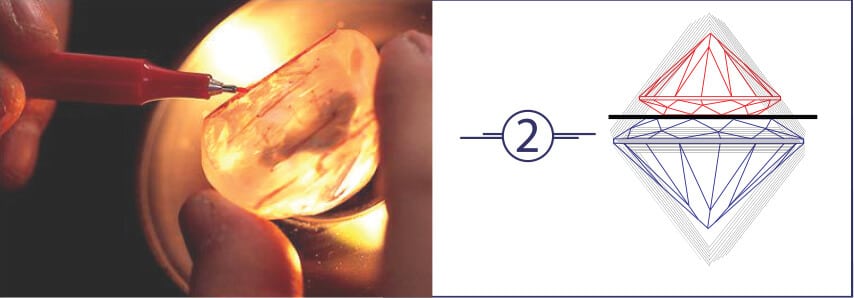

Rough to polish

Diamond cutting is the art, skill and science of transforming a raw crystal into a polished, faceted diamond. As the hardest material known to man, cutting and shaping a diamond requires specialized knowledge, tools and skill.

-

1) Planning: This rough octahedron crystal is studied and its growth directions and inclusions are mapped. -

2) Marking: Once the plan is determined, the crystal is marked for primary sawing. -

3) Sawing: A carbon-fiber blade coated with diamond-grit makes the first cut. It will take several hours to saw this crystal into two pieces; each of which will become a polished diamond. -

4) Bruting: The two pieces spin in opposite directions, grinding against each other to smooth the edges and create a round outline. -

5) Polishing: A spinning wheel coated with diamond-grit is used for blocking, crossworking and brillianteering, the process of placing, shaping and smoothing all facets to final polish. -

6) Inspection: Once finished, the diamond is thoroughly boiled in acid and examined to ensure that it meets the producer’s expectations and quality standards.

Diamond Grading

Following the diamond cutting process and prior to being sold loose or mounted into jewelry, diamonds are typically submitted to gemological institutions such as IGI for quality assessment. Four main factors are considered when judging a diamond’s quality and value. They are the diamond’s 4C’s: Carat weight, Color, Clarity and Cut.

IGI screens every diamond using state of the art technologies to determine naturally mined, laboratory grown or simulant origin. Experienced graduate gemologists conduct further assessment in controlled conditions, detailing relevant gemological characteristics according to the strictest international system.

Uniquely yours

Your diamond is exceptional and distinctive. No two diamonds are alike. Yet all diamonds have certain features in common that allow experts to compare and evaluate them.

The name diamond is derived from the ancient Greek “adamas” meaning unbreakable, untamed and unconquerable. Diamonds have been treasured as gemstones ever since they were discovered. In our modern age the word “diamond” continues to evoke images of elegance, style and glamour.

Diamond sparkles and dazzles. Diamond symbolizes purity and strength. And the story of your diamond is uniquely yours.

Your Diamond's Story

Your diamond was forged between one and three billion years ago deep beneath the earth's surface. A powerful process called subduction, where ancient land masses moved against each another, produced enough pressure, friction and heat that fragments of carbon crystallized and grew into our planet's supply of natural diamonds.

Volcanic delivery

Your diamond began its extraordinary journey toward your hands with a volcanic ride to the surface. Some diamonds lodged in the volcano’s throat. Others were blown clear and distributed over a large area by rivers of magma. Rain, erosion, ice-ages and other forces of nature, sustained for millions of years, buried some diamonds and released others from their mother rock - transporting them hundreds of kilometers away.

Diamonds have been discovered on nearly every continent. The most abundant gem-quality deposits are mined in Africa, Russia, Austalia and Canada.

A history beyond conception

Every natural diamond crystal has a history beyond conception and a forever-story larger than life. Billions of years old, your diamond existed before the dawn of man. Before tribes, clans and nations. Every diamond underwent a staggering growth process and made an extraordinary journey over countless ages before its discovery. Once recovered and sorted, your rough diamond crystal was sent for planning and cutting.

Rough to polish

Diamond cutting is the art, skill and science of transforming a raw crystal into a polished, faceted diamond. As the hardest material known to man, cutting and shaping a diamond requires specialized knowledge, tools and skill.

-

1) Planning: This rough octahedron crystal is studied and its growth directions and inclusions are mapped. -

2) Marking: Once the plan is determined, the crystal is marked for primary sawing. -

3) Sawing: A carbon-fiber blade coated with diamond-grit makes the first cut. It will take several hours to saw this crystal into two pieces; each of which will become a polished diamond. -

4) Bruting: The two pieces spin in opposite directions, grinding against each other to smooth the edges and create a round outline. -

5) Polishing: A spinning wheel coated with diamond-grit is used for blocking, crossworking and brillianteering, the process of placing, shaping and smoothing all facets to final polish. -

6) Inspection: Once finished, the diamond is thoroughly boiled in acid and examined to ensure that it meets the producer’s expectations and quality standards.

Diamond Grading

Following the diamond cutting process and prior to being sold loose or mounted into jewelry, diamonds are typically submitted to gemological institutions such as IGI for quality assessment. Four main factors are considered when judging a diamond’s quality and value. They are the diamond’s 4C’s: Carat weight, Color, Clarity and Cut.

IGI screens every diamond using state of the art technologies to determine naturally mined, laboratory grown or simulant origin. Experienced graduate gemologists conduct further assessment in controlled conditions, detailing relevant gemological characteristics according to the strictest international system.

Your diamond is exceptional and distinctive. No two diamonds are alike. Yet all diamonds have certain features in common that allow experts to compare and evaluate them.