The 5th C: Confidence

The 5th C: Confidence

Diamond grading at IGI follows a strict sequence of intake, analysis and reporting to ensure the highest standards of security, anonymity, accuracy and consistency.

Learn more with videoAnonymous Unique Report Number

Diamond grading is entirely anonymous. Upon arrival to IGI, every diamond receives a unique auto generated IGI identification number. To ensure neutrality and objectivity all owner information is masked. The IGI identification number, exclusively, is seen by graders. The diamond returns to central control following each stage of grading, to randomize the gemologists who examine it. After grading the unique report number becomes the official IGI grading report number, accessible with the Verify Your Report feature.

Compulsory Screening

IGI performs the industry’s most advanced screening and detection services on every diamond, gemstone and jewelry item submitted for analysis. State of the art technologies are used to determine naturally occurring, laboratory grown or simulant origin. The world’s most prestigious brands rely on IGI as their authoritative resource for authenticity and quality assessment of diamonds and gemstones of all categories, classifications and weights.

IGI was the world’s first global institute to receive ISO 17025 certification for natural and laboratory grown diamonds.

![]()

The Grading Process

The Grading Process

Over the last 50 years, IGI has developed strict grading protocols to ensure consistency and transparency for both consumers and dealers alike. An IGI report is used and respected around the world to support the buying and selling of precious gems

Learn more with video

Step 1

Carat Weight

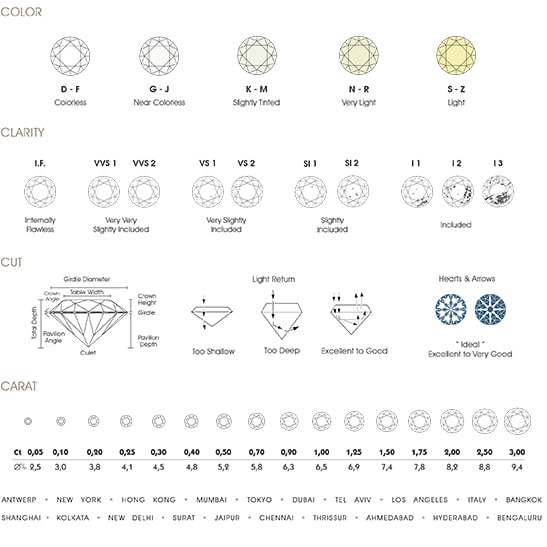

The first stage in diamond grading is weighing the diamond. Carat weight is the standard weight unit for gemstones. Diamond grading scales are calibrated to four decimal places to ensure accuracy. Carat weight is reported to two decimal places.

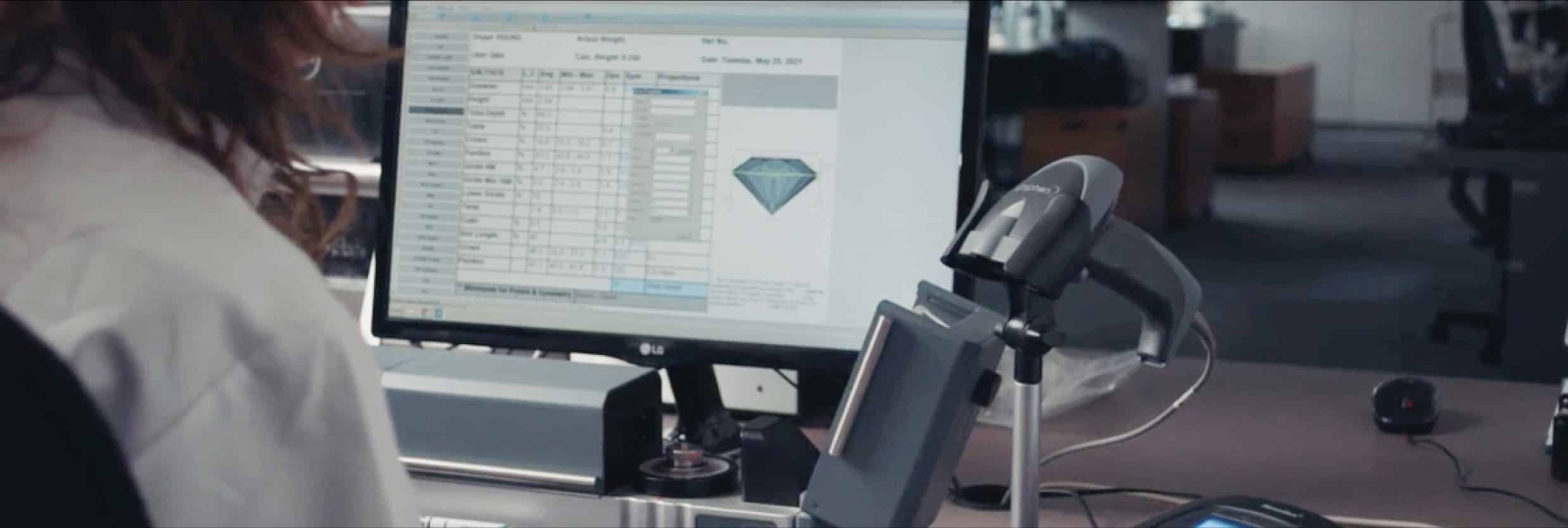

Measurements

The diamond’s measurements are established using a gemstone-specific optical measuring device. The scanner creates a 3D digital sculpture of the faceted stone’s total geometry, including all proportions, measurements and facet angles. Key measurements are printed on the diamond’s grading report.

Step 2

Color and Fluorescence Grading

Diamond color is graded in a standardized viewing environment. IGI gemologists analyze color in the D to Z color range with the diamond placed upside down, viewed through the side, to facilitate a neutral view. Grading color from the top is not practical because of three factors which may influence color appearance in normal viewing.

- The diamond’s shape

- The way the diamond was cut

- The presence of fluorescence

Color is graded using calibrated master color stones. The color grading process involves multiple graders submitting opinions independently, with no internal communication.

Fluorescence Grading

Fluorescence is a measure of the diamond crystal’s reaction to ultraviolet (UV) light. Around 35% of all diamonds emit fluorescence when subjected to UV light. If fluorescence is present, the strength and color of the fluorescence is recorded.

Step 3

Clarity and Finish Grading

IGI grades clarity according to internationally accepted standards at 10X magnification, according to the visibility, size, number, location and nature of internal and surface characteristics at that magnification. Diamonds with characteristics which are immediately obvious or noticeable are likely candidates for the lower grades, whereas diamonds with characteristics which are minor, minute or extremely difficult upon initial analysis at that magnification may qualify for the higher grades.

Plotting

The gemologist will use a step by step wedge technique, examining the diamond in segments, to note the location and nature of all relevant clarity characteristics. A map of the diamond’s internal and external clarity characteristics, as observed at 10X magnification, is provided for purposes of information and identification on a diagram representative of the diamond’s shape and faceting style.

Step 4

Cut Grading

IGI assesses craftsmanship components for all diamonds – with cut grading and optional light performance reports for round brilliant cuts – and a cut grading option for fancy shaped diamonds.

Round Brilliant Cut Diamonds

IGI assesses all round brilliant cut diamonds in the areas of polish, symmetry, and proportions. The top cut grade a round brilliant diamond can earn is Excellent-Ideal. The overall proportions, measurements and facet angles determine the Cut Grade. If the polish and symmetry assessments are lower than the grade according to overall proportions they may cause the overall cut grade to be lowered.

Light Performance Report for Round Diamonds

Diamonds of the same shape, size and cut grade can have different visual tendencies. For this reason IGI offers a light performance report option for round diamonds displaying top optical performance, which provides a primary Light Performance score and scores for three observable sub-components; Brightness, Fire and Contrast.

- See a video overview of the Light Performance Grading process

- See and download the IGI Light Performance Cutting Guidelines

Cut Grading for Fancy Shaped Diamonds

IGI assesses all fancy shaped diamonds in the areas of polish, symmetry, and proportions. All shapes and colors will have craftsmanship grades for polish and symmetry noted on the grading report. Cut grading for fancy shapes ranges from Excellent to Poor based on the process and parameters linked below, and is optional.

- Scroll down this page for a video overview of the Fancy Shape Cut Grading process

- See and download the IGI Fancy Shape Cut Grading Guidelines for Excellent

Step 5

Verification

In the areas of color and clarity analysis multiple gemologists take the diamond through the grading steps and provide opinions, completely independent from the others. Color and clarity grades are only finalized when a consensus is reached.

Step 6

Grading Controls

Between each grading step, a diamond returns to central control, to various gemologists is completely random. Every diamond is electronically tracked so that central control knows its location at any time and may review each step in the process.

Step 7

Laser Inscription

IGI’s LASERSCRIBE SM, combined with the standard of excellence and recognition of IGI’s Diamond Grading Reports assures you of both the quality and identification of your diamond. In fact, every laboratory grown diamond IGI grades will have an inscription identifying laboratory grown origin automatically applied.

For natural diamonds the laboratory will apply laser-inscriptions by owner’s request, typically the diamond’s grading report number. If the diamond belongs to a brand or specific store, the owner may also have a logo inscribed.

Step 8

Report Printing and Security

Diamond grading reports are printed on advanced security paper with no less than five security features. These include tear proof paper, micro printing, holographics and other security features. The diamond is weighed, verified as matching the report by central control, cleaned and prepared for return to its owner along with the new diamond grading report, which is placed in a protective sleeve or binder.

Step 9

Digital Grading Report Posted

Once the diamond and report have left the diamond grading laboratory premises a digital copy of the report will be posted online. This report is accessible using the IGI Verify Your Report feature. The QR (Quick Response) code on the printed grading report can also be scanned by a QR code reader and will take the user to the corresponding grading report, posted online.

Consumer Education

IGI consumer education is designed to prepare shoppers to make informed decisions when buying or selling diamonds, gemstones and jewelry.

Enroll in our Diploma Programs

IGI trains jewelry professionals in more places around the world than any other institute, offering an array of campus and online courses which are unrivaled in diversity and reach.