Our new Lab Grown Diamond page is live

Are lab-grown diamonds real?

Yes. Lab grown diamonds are not simulants like CZ or moissanite. Lab-grown diamonds are not “fakes.” Aside from subtle carbon distinctions, they are chemically identical to natural diamonds. The technical difference is that they’re not billions of years old. Lab-grown diamonds are grown in factories using sophisticated chemical synthesis over a period of 1-4 weeks. Once grown, they are polished with the same tools and brought to market in the same manner as natural diamonds.

Are Lab Grown Diamonds Synthetic?

Lab grown diamonds are created through chemical synthesis, but the FTC considers that term confusing. So, while you may see the word synthetic in science journals and research papers the diamond industry widely uses the term lab-grown.

Do lab-grown diamonds look the same?

Yes. Lab-grown diamonds have identical refractive index and optical qualities. Lab-grown diamonds are even graded using the same color and clarity scale as natural diamonds. Experienced gemologists and jewelers may be able to identify characteristics that point to lab-grown origin, but in casual viewing, they are identical to natural diamonds.

Are lab-grown diamonds less expensive?

Yes. Lab-grown diamonds trade for lower prices than comparable natural diamonds. The principle of accelerating change suggests that technological improvement may ultimately make them even more cost-effective to produce. With that said, at some point, producers are likely to stabilize pricing, much like miners and sight holders have done across the natural diamond industry.

Are lab-grown diamonds sustainable?

In most cases no. The energy required to power lab-grown diamond plasma chambers and presses is immense and many growers burn fossil fuels to power their reactors. However, there are some operations employing hydroelectricity that can prove lab-grown diamonds are sustainable.

What if sustainability is important to me?

Look for the appropriate IGI lab-grown grading report. SCS Global has developed a sustainability certification for natural and lab-grown diamond producers. When a producer submits a stone to IGI along with proof of sustainability, IGI will identify that stone as certified sustainable on the grading report.

How are lab-grown diamonds created?

HPHT

High Pressure, High Temperature (HPHT) replicates the natural conditions under which diamonds formed. Of course, they formed around 100 miles below the earth’s surface a billion years ago as continental drift dragged land masses across each other. The process employs anvils, heating, and pressure apparatus applying significant pressure and heat to a small cell over a period of days or weeks.

The small cell contains a seed crystal, a metal catalyst, and carbon powder. It will be heated to between 1300 and 1600 degrees Celsius. Note that the top of the cell will be heated a small percentage hotter than the bottom of the cell. This is to keep the melt happening from the top down.

Anvils apply massive pressure from all sides (approaching 900,000 pounds per square inch). The HPHT process results in liquification of the catalyst, which starts dissolving the carbon. That melted carbon moves from the higher temperature to the lower temperature, migrating through the flux to the diamond seed crystal. Upon reaching the cooler seed, the carbon material crystallizes on it and the seed stimulates the growth of a new lab-grown diamond.

CVD

Chemical Vapor Deposition (CVD) occurs in a vacuum chamber. It begins with a flat substrate of diamond seed crystal. The chamber is depressurized and filled with hydrocarbon and hydrogen gases. Microwaves heat those gases until the electrons separate from their nuclei, forming plasma.

Hydrogen and carbon atoms precipitate from the superheated plasma cloud and rain down on the substrate. Under ordinary circumstances, this process would only grow graphite, but the hydrogen atoms etch the graphite away, permitting the carbon atoms to pair with the diamond substrate, crystallizing atom by atom and growing vertically upward.

Distinctive Inclusions

Metallic flux in HPHT

One by-product of the HPHT process is the possibility of metallic inclusions. If you recall, a metallic catalyst is used to dissolve the carbon which migrates to the diamond seed. Logically, pieces of that metal catalyst that do not melt entirely can become trapped within the diamond crystal.

The most frequently seen characteristic in HPHT-produced diamonds is a dark, rod-shaped metallic inclusion. These flux inclusions can have a man-made appearance when seen under magnification, and can even be reflective, unlike any naturally occurring inclusion type.

Stria and planar inclusions in CVD

In the CVD process, no pressure is applied. Carbon rains down on the substrate, growing that crystal vertically in parallel layers. During the process, crystal growth may undergo a series of stops and starts. In such cases, you may see graining within the diamond which presents as extremely flat since it took place on a single linear horizontal plane.

Another by-product of vertical growth, and a process that may have stops and starts or includes contaminants, are characteristics that become grouped together on a single linear plane within the finished crystal. Such structured planar inclusion groups rarely/never occur in natural gemstones.

Experienced diamond cutters, gemologists, and jewelers are improving in their ability to identify certain lab-grown diamonds with loupes and microscopes.

Quality Control Factors

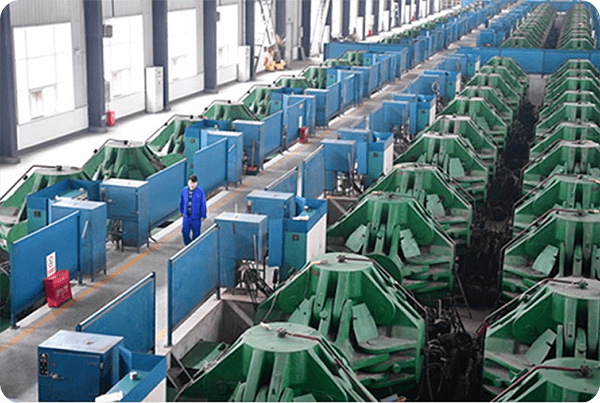

In the past several years the rising visibility and popularity of lab-grown diamonds has created a “lab-grown diamond rush.” As more and more growers enter the arena, lab-grown rough output has taken on more variability. This can be exaggerated by entities entering the field with less capital resources, lower quality equipment, presses converted from industrial to gem-quality use, contamination confounders, etc. Turnaround choices also play a role. When a growth process is pushed to maximum speed it will increase the grower’s output, but also increase the likelihood of inclusion types which experienced gemologists can identify as distinctive to lab-grown diamonds.

How are lab-grown diamonds graded?

Following the diamond-cutting process and prior to being sold loose or mounted into jewelry, diamonds are typically submitted to gemological institutions such as IGI for quality assessment. IGI screens every diamond using state-of-the-art technologies to determine naturally mined, laboratory-grown grown, or simulant origin. Experienced graduate gemologists conduct further assessments in controlled conditions, detailing relevant gemological characteristics according to the strictest international system. Four main factors are considered when judging a diamond’s quality and value. They are the diamond’s 4C’s: Carat weight, Color, Clarity, and Cut. IGI Explains the 4Cs and More – Learn With Videos