Your jewelry was conceived and fashioned by dedicated professionals from start to finish.

- Conception: A design was drawn using hand-sketches or CAD software

- Creation: A hardened mold was produced to accomodate your jewelry’s forging

- Casting: The molten precious-metal alloy was delivered into that mold under consistent pressure, promoting bonding, density and strength

Your jewelry was carefully removed, refined and cleaned, undergoing a rigorous dual-process of fine-tuning and polish prior to setting, whereafter it was thoroughly inspected for durability and quality, as well as beauty.

The process of jewelry-making

From artistic collaboration and direction to forging and cooling to detailed clean-casting and pre-polish. From secure, precision stonesetting to hours of final polish, every step was deliberate and meticulous.

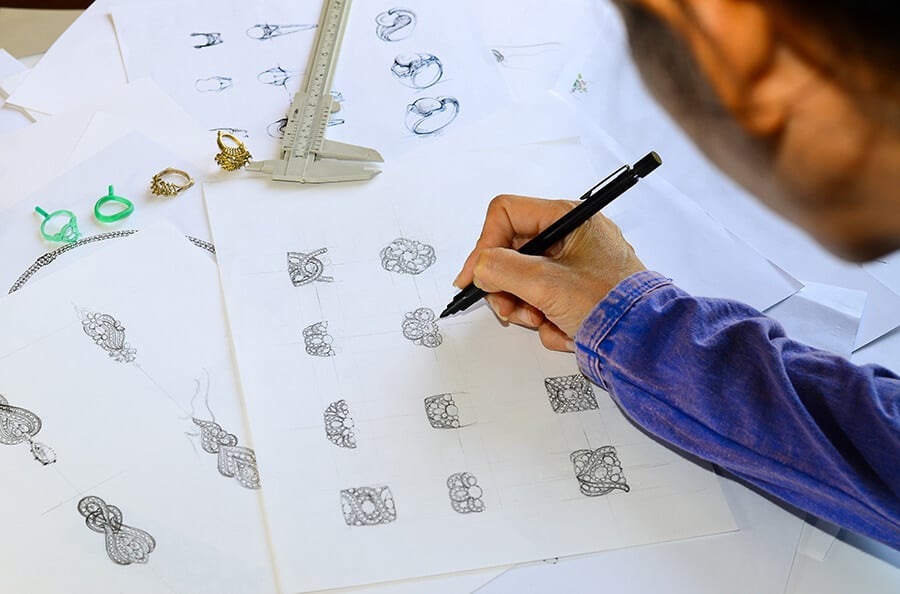

Conception

Your piece was designed by visionaries. It may have been an artist using hand-sketches or a gemology graduate using modern CAD software. Professional jewelry designers must command both the basics and complexities of jewelry creation to perfectly balance the primary components of aesthetics, durability and cost.

Creation

An exact replica of your jewelry’s mounting was created in modeling wax. Whether hand-carved or rendered with high-precision 3D printers, that replica was refined to become a twin of your precious item. That twin was placed into a casting flask and encased in jewelry-quality investment. The investment hardened to form a perfect negative-replica mold, suitable for casting. Its job finished, the wax was superheated and removed with vacuum technology.

Casting

Your mold was taken to the foundry and your precious metal was brought to its melting point in a crucible. The metal alloy was delivered to the mold in a casting centrifuge with high-pressure inert gas, forcing your alloy into sub surface voids and facilitating diffusional bonding to promote density, strength and durability.

Cleaning

When finished and cooled your jewelry was carefully removed from the mold. It underwent the rigorous dual-process of clean-casting, where excess material was removed, and pre-polish, where the piece was thoroughly inspected and verified for fundamental quality and integrity.

Culmination

Stone-setting and polishing brought your finished jewelry to life. The setter meticulously balanced, seated and secured your gemstones, and the polisher brought all details of finish to culmination.

From conception to creation, a talented array of professional specialists took deliberate and meticulous steps in the careful forging of your jewelry.